Our Installation Process

Timber Cabins UK is a company involved in the construction of timber cabins for both Holiday Homes and Residential Homes, Extensions and extra rooms for properties. We have been in operation for over 15 years and operate nationwide.

Our philosophy towards construction is design and build without compromise; using the best-proven techniques and materials available to achieve the highest quality standards.

Our ethos is to be the best in class. This we always strive to achieve through a relentless pursuit of improvements and product development.

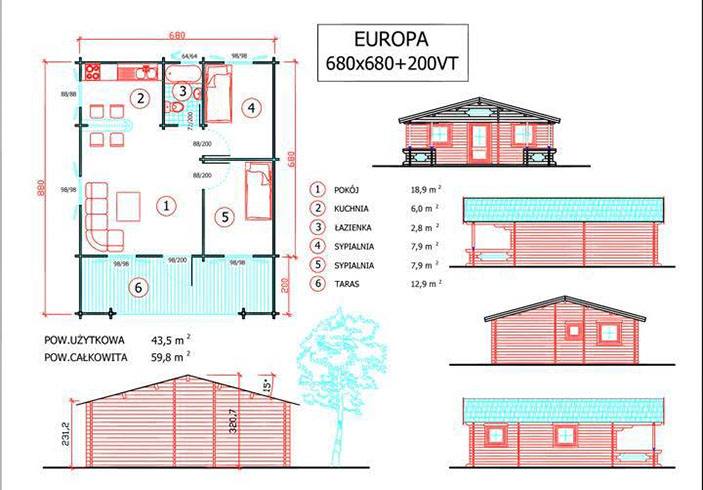

Our range of Timber Homes and buildings can be made to any size to suit your requirements, perfect for that extra room for when guests arrive or maybe just a relaxation room to allow you to get away from it all at the end of a day’s work.

We can custom build any type or size to suit your needs or, choose from

our standard range buildings.

1. Plan Your Dream Log Cabin

Think about what kind of log cabin you need, what it should be used for, what size it should be, whether it should be storeyed, whether it should have a balcony or terraces, whether it be a year-round house with insulation and heating or the only seasonal house for sauna or hot tub. Should there be two bedrooms or one, a kitchen connected to the living room or a separate kitchen and a separate living room with a terrace, how big the bathroom will be, how many windows will the house have, where will it stand on your plot?

When you think and discuss all the details with your family and friends, contact us and we will prepare our projects for your individual needs.

2. Preparing the Project

In order for a house to be built, it must first be designed in a computer program so that, after sending it to the production hall, the cutting machines know how to work with wood. Such a project should be prepared by a person with experience. Of course, you can prepare your design on a sheet of paper drawn with a pencil, our architect will convert it into an appropriate electronic design.

When we will arrange all the details and you will take care of all official matters and permits related to building the house, we will send the design to the production hall.

3. Wood Preparation in the Production Hall

To build a log cabin or summer house, you need wood that must be cut at first , next processed, dried and impregnated. This is a long-term process. Don’t worry, we have enough wood in our warehouses. Our houses are made entirely of natural and ecological material, we usually use spruce wood, which was previously planed, dried and impregnated.

In the manufacture, wooden logs are planed and cut to appropriate lengths, and the produced elements are pre-assembled to make sure that they all fit together perfectly.

4. Preparation of the Ground and Floor Installations

When your house is being built in the production hall, it is the right time to prepare a place for it.

For the construction of our houses, we recommend a classic cement screed insulated against moisture. The screed should be prepared in accordance with the design, taking into account local geological conditions.

It is very important for wooden log buildings to preserve the screed geometry, in other words, the accuracy of the screed dimensions and the diagonal level.

The screed slab should be properly protected, e.g. pre-insulated against moisture by painting with bituminous agents. If you are planning a sewage system, you should also prepare it. If the chimney, then it should be built. Preparation of the area for construction and screed slab is on the investor’s side, we do not make screed slabs or chimneys.

Log cabins up to 30m2 can be put on concrete blocks that we will deliver with the house. In this case, prepare and level the ground properly.